Accelerator pump carburetors for Suzuki DR650

- Jonathan Binnington

- Jul 9

- 6 min read

Much opinion has been passed about the fuelling of Suzuki’s DR650. As it comes, the DR has a Mikuni BST40 constant velocity/vacuum slide valve carburetor. The carburetor jetting is set on the lean side of lean in order to meet stringent exhaust gas emissions requirements.

Very quickly I realise there is much knowledge behind this subject that needs to be understood before we can go forward with this discussion of the why’s and wherefore’s of alternative carburetors, so here goes on an introduction course on one of the “black arts”.

What does a carburetor do?

Fundamentally, a carburetor is a device that allows the motorcycle rider to meter the amount of air going into the engine and mixes fuel (petrol, gasoline, essence) into that air at precise ratios of fuel:air to meet different engine requirements.

The air valve is a butterfly disc valve that closes the throat of the carburetor to “throttle” it into submission.

The metering and mixing of fuel occurs as the air that is drawn through the carburetor by the engine passes over an jet orifice that connects to a fuel reservoir (float bowl) below the narrowest part of the carburetor. The fuel is drawn up from the reservoir by Venturi action - a partial vacuum generated when air is sucked through a narrow space.

This is the central point to the function of a carburetor.

There are complications though, the amount of fuel sucked into the airflow through the carburetor depends on the vacuum at the opening of the jet - higher airflow speed equals a greater vacuum and more fuel per amount of air (richer mixture). Conversely, lower airflow speeds create a lower (or no) vacuum at the jet and a much leaner mixture. Sometime so lean the petrol won’t actually burn…

Air:fuel ratios and stociometry.

Stociometry in chemistry is the branch of that science that describes the quantities of reactants in a chemical reaction.

Petrol has a very specific chemical makeup. It is a mix of liquid hydrocarbons and there is no need to describe that any further. It takes 14.7 units (grams, or whatever your preferred measurement is) of air to completely burn 1 unit of petrol. All the hydrocarbon will combine with atmospheric oxygen to produce carbon dioxide and water vapour (CO2 and H2O). No oxygen left over, no hydrocarbons left over.

Catch is, the stociometric ratio isn’t always the best for every situation.

Air:fuel mixtures that have an excess of air (oxygen) can be beneficial for fuel economy - if you can get it to burn (but there may be other disadvantageous consequences).

Air:fuel mixtures that have an excess of fuel can be beneficial for power production - but your fuel economy will take a hit (and there may be other disadvantageous consequences).

Motorcycle riders like powerful motorcycles.

Der! Of course…..!

The two types of carburetor.

Carburetors can be divided into to separate designs.

Slide carburetors have the butterfly or air slide directly connected to the throttle twistgrip and the rider directly controls the opening of the carburetor. There are some operating conditions where the function of the carburetor is less than optimal and the rider has to use skill to avoid these conditions. For example low engine speed with high engine loads and wide throttle openings. (Remember, the air flow speed over the fuel jet falls greatly in this condition and the fuel:air mixture goes lean and the engine stops producing power = stall).

Constant Velocity carburetors - the movement of the throttle valve doesn’t directly control the opening of the carb, but instructs the carburetor to open at a rate determined by the springs and diaphragms inside. This type of carburetor is much more immune to ham-fisted operation, only opening by as much as the engine can cope with incoming air. In many ways, CV carburetors are more pleasant to use as they have this degree of automation in their operation.

Extreme operating conditions.

Riders like power. Skilled riders like immediate power. If you want an engine with “snappy” throttle response, such as in competition, a slide carburetor will (probably) give you what you are after.

But, we have already describe the operating condition where a slide carburetor is opened quickly at low engine speed and it’s fuel metering capability fails, the mixture goes lean and the engine dies…

So, what happens if yo arrange for a little fuel pump in the carburetor to squirt extra fuel straight into the carburetor throat every time the throttle is opened to counteract the leaning condition that we don’t want?

Enter the accelerator pump slide carburetor. Good for throttle response and low/midrange power, not good for fuel economy….

What? You want it all….. No Can Do!

Now we are at our starting point for this tale.

The factory BST40 carburetor is very good at handling the demands of a “high” performance, large displacement single cylinder engine that is required to meet stringent exhaust emissions standards. It can handle large throttle openings at low engine speeds and not cause the engine to stall, at the same time as being able to provide good power at medium and high engine speeds - and return reasonable fuel economy.

But if you want to maximise engine performance at the expense of fuel consumption, the only way to realistically go is with an accelerator pump-equipped slide carburetor.

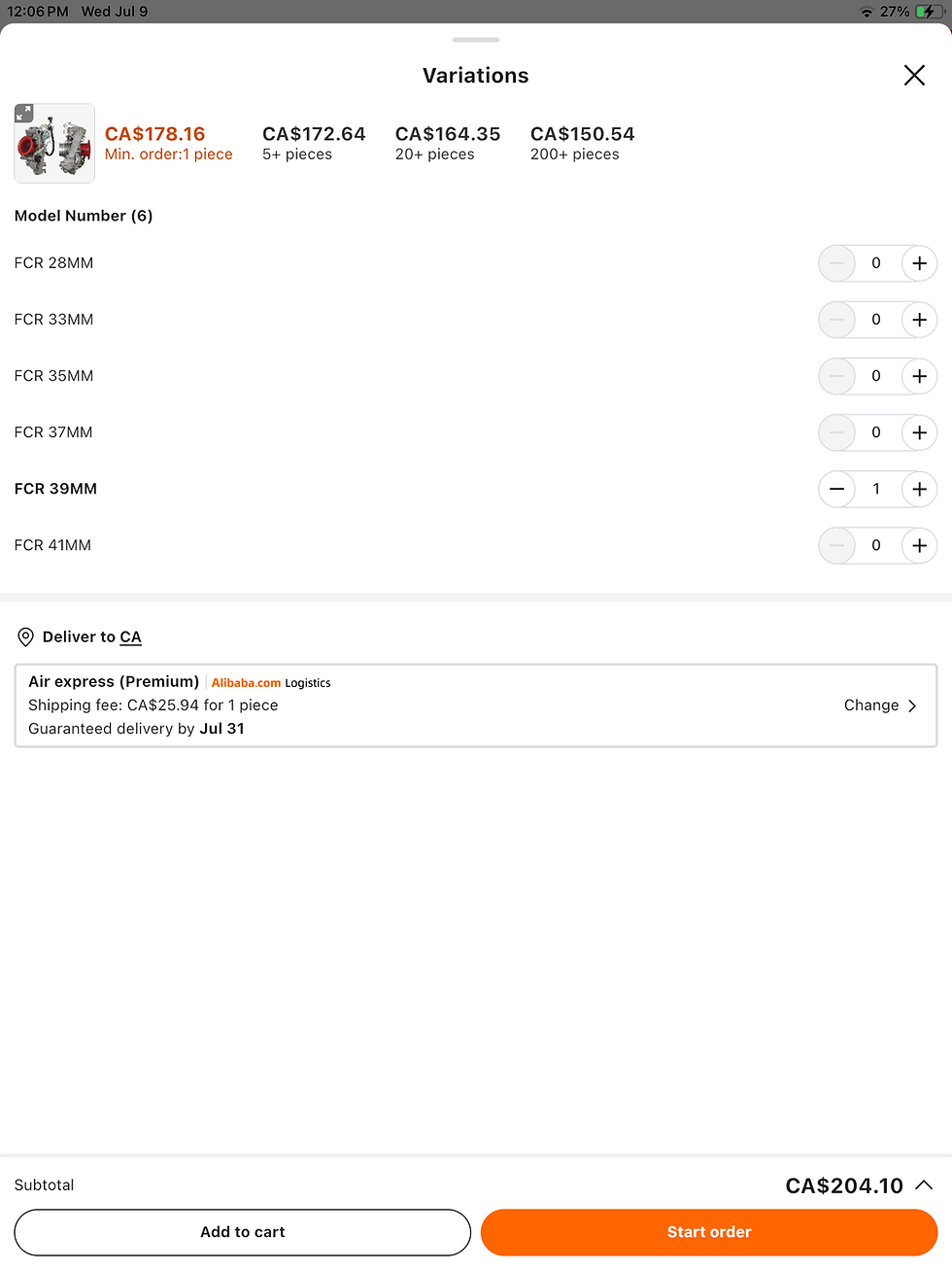

An advert for a Chinese-made carburetor of this description came across my social media feed. I opted for a carburetor that was based on a Keihin FCR carburetor, and I chose a 39mm Venturi size. It wasn’t expensive.

Out of the box…

The 39, as it comes, has a screw-on adapter for the cylinder head rubber intake stub and a short plastic velocity stack that didn’t fit the Suzuki airbox.

There were various carburetor body openings that obviously were part of the plumbing when combining multiple carburetors for multi-cylinder engines and of course there were no recommendations on jet sizes.

Fitting this carburetor IS NOT a Saturday afternoon job!

You will need a lathe (to rework the cylinder head adaptor),

A specific air box adaptor,

Keihin genuine accelerator pump internals,

Various fuel pipe fittings to block off or reroute the redundant carburetor body openings.

All in all, I probably put twelve to fifteen hours of thinking and working time. And I have a lathe…

Yow will need to:

Rework the cylinder head side stub to fit it to the carburetor body and the intake stub on the cylinder head. Match the dimensions on the BST40. Need a lathe.

Replace the airbox side stub with one that matches the Yamaha YZF450. I stripped the copper wires out of a short length of 14g electrical wire and used the empty insulation “tube” as an O ring for the stub to carb body seal.

Replace the accelerator pump internals with genuine Keihin parts (diaphragm and spring).

I would rate the job as trickier than fitting tyres but not as tricky as rebuilding a gearbox. A lathe is a must.

Having reproduced the dimensions of the BST40 on the (C)FCR39, fitting it is just a matter of rearranging the pipes and cables to best suit the new carb. If you are wise, you will modify as little as possible so that if you need to revert to the Mikuni, everything swaps straight back.

I guessed at a 155 main jet and a 40 pilot jet. In practice it might be a little on the rich side but as I have the extra large Acerbis fuel tank and ride this bike only at weekends I haven’t got round to changing the main jet for a 150 yet. I’ve done about 2000 km off road since changing the carburetor with no issues, breakdowns or complications.

So how does it go?

At this point, the assumption is that you have already done the usual “uncorking” modifications to the airbox and exhaust…. Without those first steps you will probably not derive the full benefit of your labours.

Next, it is difficult to quantify exactly what the difference will be, using the usual dynamometer methods. Why? Well dyna sessions are few and far between, not cheap and they usually measure steady state engine powers and we are interested in “throttle response”.

But from my seat-of-the-pants experience…

Absolute maximum power is not changed, as a wide open CV carb has (approximately) the same airflow capacity as a wide open slide carb.

Closed to 1/4 open throttle at low and mid revs feels the same as for the CV carb.

The difference is felt between 1/4 and 3/4 throttle at 1/4 to 3/4 engine speed. The engine has more “snap, crackle and pop”.

This modification WILL NOT turn your mighty DR650 into a KTM690 or a H7101 - it does make your DR a more interesting ride, the extra throttle response can catch you out while you are getting accustomed to the new reality.

Where to get the bits and pieces and how much?

All in all, about $400 Canadian - about half the cost of a specific kit of parts. I did this this way because I wanted to see if I could. I might even do it to my new DR…

JDB 9/7/25

Comments